I Create Awesome Stuff

I have a strong background in electronics and robotics, starting with my experience on a FIRST Robotics team in high school, where I helped design, build, and program robots for competition. I mainly used Java during this time to control manual and autonomous functions of the robot utilizing various sensors and actuators for unique control systems. I attended a Vocational Technical High School where I studied Industrial Electronics alongside normal classes. This experience was unique because we had to learn the same basic classes as normal high schools but in about half the time. There I learned about Analog/Digital electronics and basic micro controller programming. This foundation in robotics/electronics led me to pursue a degree in Software Engineering, which I received from Johnson and Wales University in Providence, RI.

Throughout my academic career, I have demonstrated my ability to excel in both the mechanical and software aspects of robotics projects. For example, I was part of a small team tasked with designing and building a functional robotic arm to cut a ribbon revealing the brand new technology building on a low cost budget. I received funding from our student government to build a ROS powered autonomous RC car that was capable of SLAM Mapping and navigation through the halls of our engineering building.

In my free time, I enjoy 3D printing and developing software I have a strong interest in using these technologies to create functional prototypes and custom solutions. I tend to prototype using off the shelf electronics such as an ESP32 for its many features and low cost. I also have taken interest in Machine Learning / AI models and API’s such as OpenAI’s GPT. I have experimented with locally run models like YOLOv8 for computer vision running on my own GPU’s

I am eager to continue developing my skills and expertise and am motivated to pursue a career in these areas where I can make a meaningful impact.

As a software engineer and robotics enthusiast, I have had the opportunity to work on a number of exciting projects in these fields. These experiences have helped shape my career goals and allowed me to use my skills to make a positive impact through technology. From developing software to building and programming robots, I have enjoyed the process of bringing these projects to life and am grateful for the chance to pursue my passions.

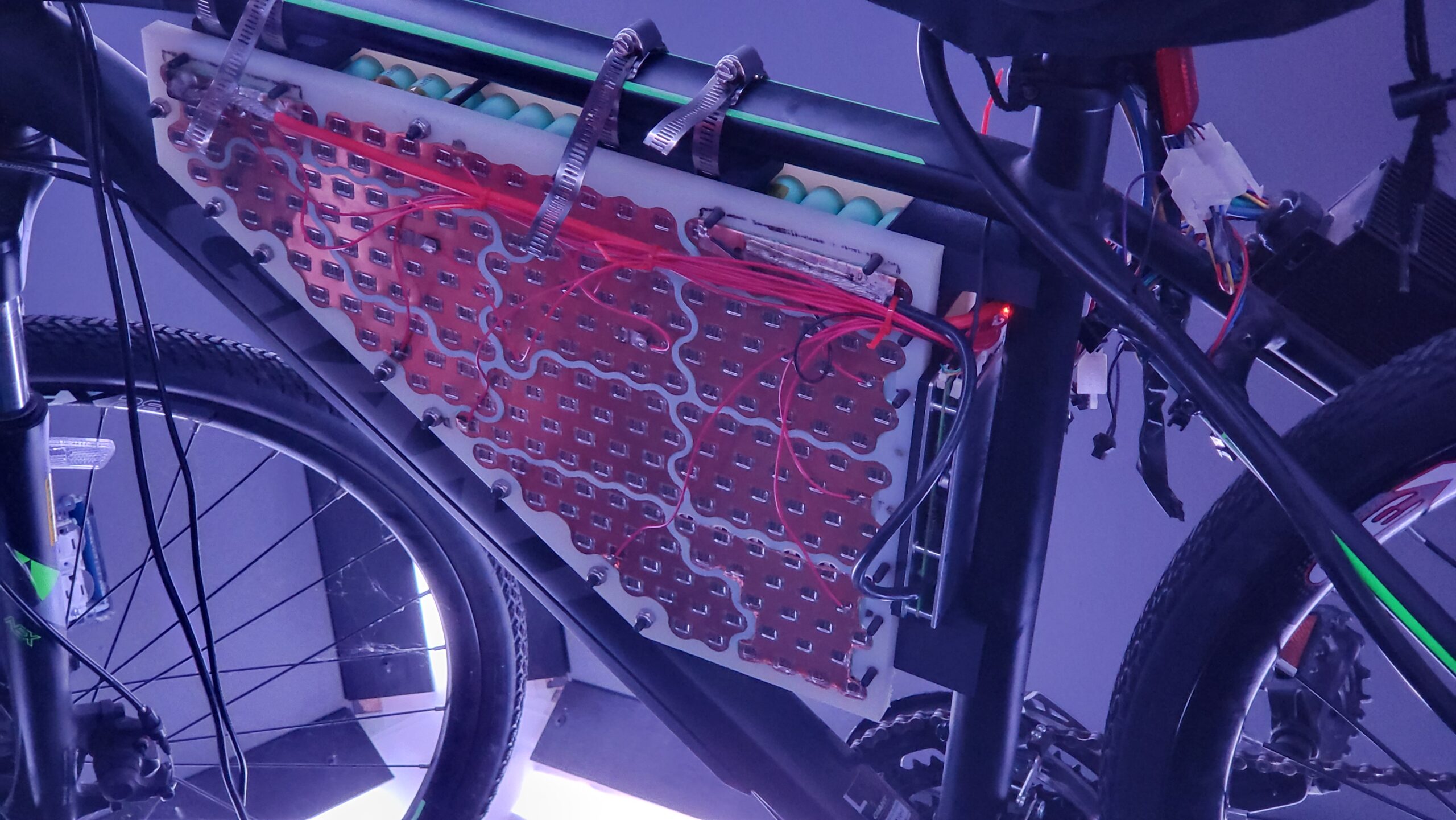

Custom built E-bike Battery

I originally bought a battery from Ebay but after a year several cells were swollen and the pack was unsafe to repair. I decided to design and build my own from scratch with generous safety margins. I designed the cell holders in Fusion 360 and planned out all the cell groupings. I then had custom Copper-Nickle fused bus bars made and used an open source spot welder to assemble the pack. Using an off the shelf BMS (Battery Management System) from JKBMS.

The pack is capable of providing nominal 72V at 100 Amps.

A web based tool for configuring esp32’s

After learning about the Web Bluetooth standard a friend and I decided to make Bleep an arduino library that lets you set parameters over bluetooth. I wrote the webapp that interacted with the bluetooth devices using the new standard.

View on Github

Adding automation to metrology

After doing repetitive tasks i figured there could be a more effecient way for measuring parts, I developed this software to communicate with a digital height gauge which gave me control of its core functions. I deployed this to a small raspberry pi with a touchscreen for quick input.

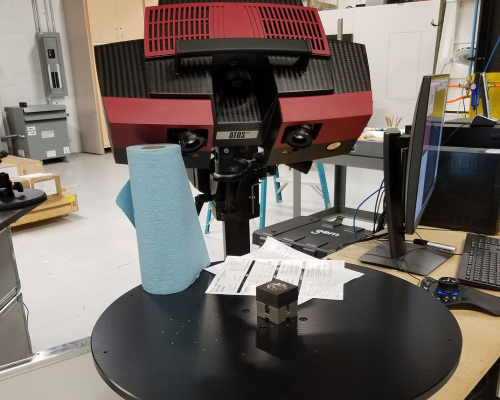

ATOS III structured light 3D scanning

I was trained on this ATOS Scanner which has a resolution of 10 microns. We used this to make reference models for texturing products using our 5-Axis lasers.

Like a tesla but way worse!

I was really interested at trying Ros in college so I put a plan together, proposed it to a board of student funding and ended up getting around $1K for the project. After many weeks and headaches taught myself quite a bit and I got a drunk RC car out of it. The school still has the car and i’ve been told some students have taken the project further.

Hand built from a kit of parts online.

After owning a Monoprice Delta Mini for some time, I really wanted to expand my work envelope for larger projects. I ended up going with Ratrigs Vcore 400 design giving me a total build volume of 400mm cubed.

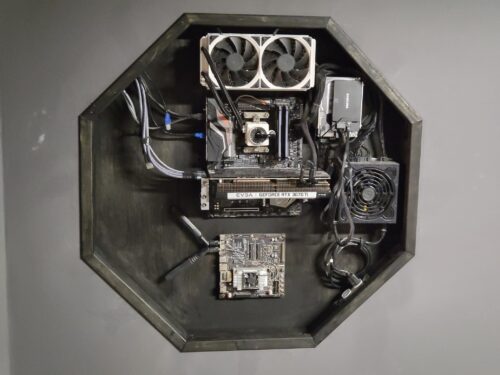

That’s right its in the wall!

As part of my game room design i wanted a futuristic look and decided to recess my PC into the wall and route all the wiring via the walls as well.

Printed from a special light weight filament on my Ratrig printer.

I printed this model from PlanePrint.com using LW-PLA pre-foamed filament for its lightweight properties it works well for 3D printed planes. The parts are printed in many pieces attached with hobby CA glue.

The fastest quadcopter i’ve ever flown.

We built a robot to cut a ribbon

We were tasked by the Dean to create and build a robot to cut the ribbon for Johnson & Wales brand new technology building which was quite an honor to take part in. I worked on most aspects of the project because of my prior experience with FIRST Robotics.

Custom outdoor LoRAWAN Gateway

I built this to experiment with cheap LoRa eps32 modules. It uses and off the shelf raspberry pi and a RAK2245 Pi Hat.

Added addressable leds to use as brake and turn lights

I enjoyed messing around with these WS2812 addressable leds and though why not put them on my motorcycle and make them functional at the same time. I added a microcontroller to sense when the turn signal was active and play an animation on the strip of leds.

For making custom batteries

From building custom battery banks to repairing my ebike battery. This DIY Spot welder worked really well for the job.

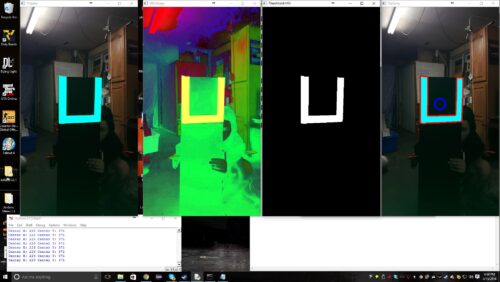

Giving robots eyes!

During our competitions with FIRST Robotics robots had a short period of time to act on their own to try and score before drivers could take control. I was able to come up with a robust solution that proved itself on the field.

I have been able to work with many frameworks and languages

My vast background has allowed me to work on projects from all aspects such as electronics concepts to fully functional prototypes, software, designing, 3D printing and manufacturing with multi axis mills. Over the years I have explored different languages, tools, and created some of my own to help automate industrial machines and my personal equipment. I have worked with small groups to reverse engineer communication protocols for Augmented Reality glasses allowing for several open source drivers to be made.

I consider one of my greatest skills to be adaptability as I learn rather quickly and have an internal drive to explore and progress in my free time.

Email me or send a message